Infeed system

We can also help you with an inline system or pulley brake system for your twister.

Besides the standard capstan brake system, we offer inline- or pulley-break system for multiple yarns and special applications.

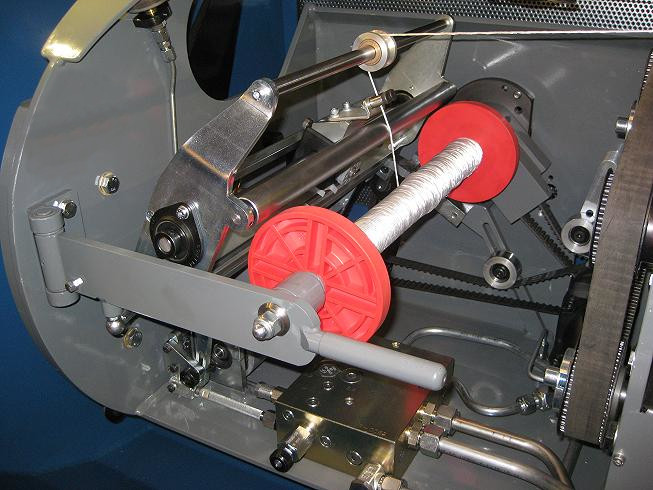

Cross-laying unit in a new design

We have designed a new and improved version of our cross-laying unit, the CLU11, for our Tornado twisters and for the T5000.

The CLU11 is easier to maintain and has a longer life than former generations of our cross-laying units. You can read more here.

We also offer a various amount of traverse lengths and yarn guide designs for both “old” types of cross-laying units and the new version of the cross-laying unit.

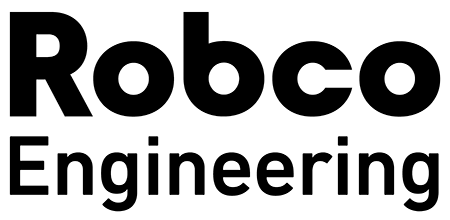

Flyer arms

Different yarn types often require special flyer arms in order to obtain the best product quality.

We offer flyer arms with different eyelets, rollers and with reinforcement for heavy yarns.

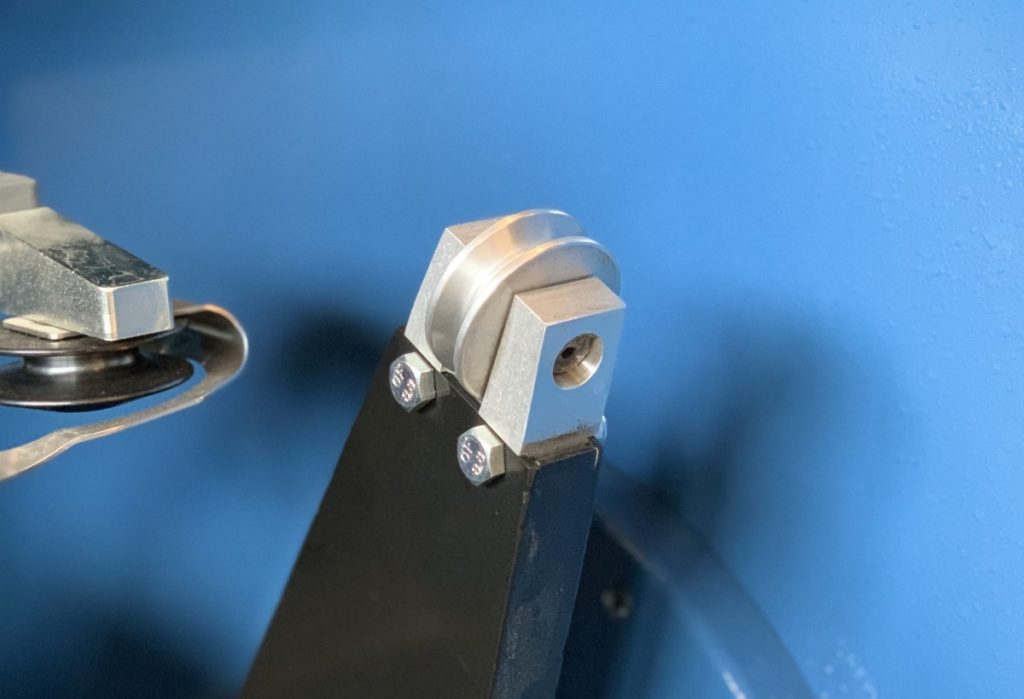

Pulling capstans

The use of the right pulling capstans is important in order to obtain the best product and bobbin quality.

To avoid sliding of the yarns and to obtain a smooth operation of the machine, it is essential that the size and amount of grooves in the capstans fit completely.

We offer capstans with different groove sizes and coatings.

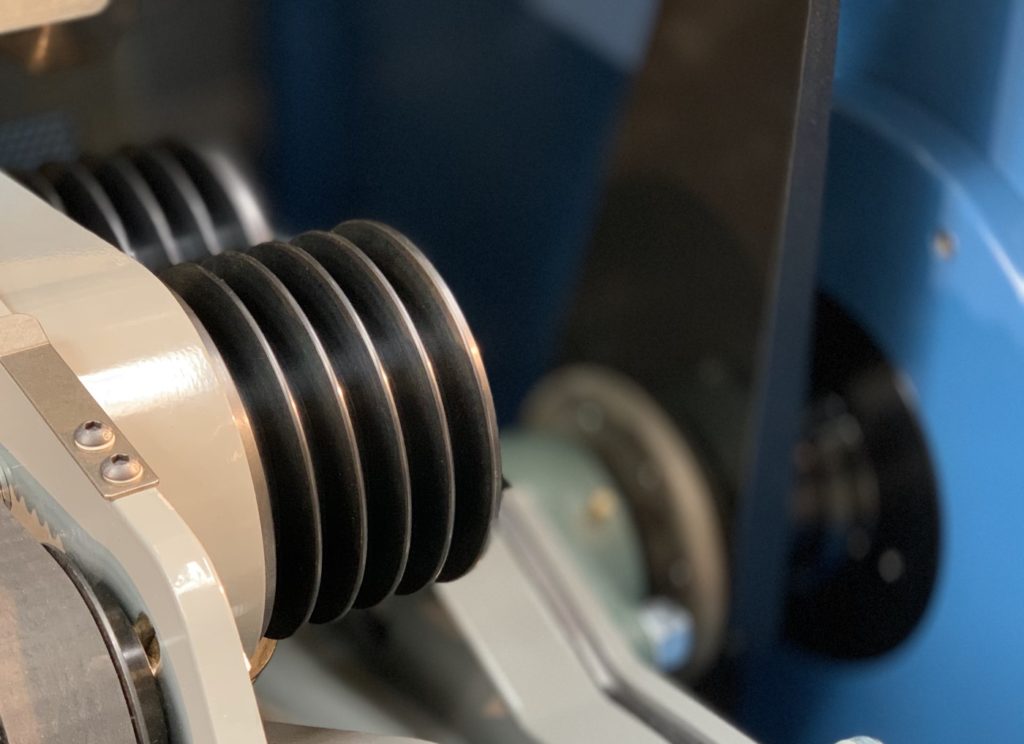

Semi-automatic doffing system with pneumatic take-up spindle

We can retrofit the above upgrade with the following advantages for the operators:

- Easy and fast bobbin change

- No use of handle for take-up spindle

Parallel winding unit

We can offer you take-up for parallel winding on braider bobbins or take-up on reels.

The parallel winding unit is customized and can be supplied with or without support arm.

Various customizations

A correct configuration of the machine is mandatory to get the absolutely first quality of your bobbins. We can help you make that happen by means of original spare parts and several years of intense knowledge of our machines.

In addition to a machine repair or overhaul, we can offer you an optimization of the machine configuration and settings to match your product.

Usually, we will ask you to send us some of your own yarns in order to test and optimize the twister in the best possible manner for your purposes. Alternatively, we will optimize the machine and process by a visit of a Robco Service Engineer.