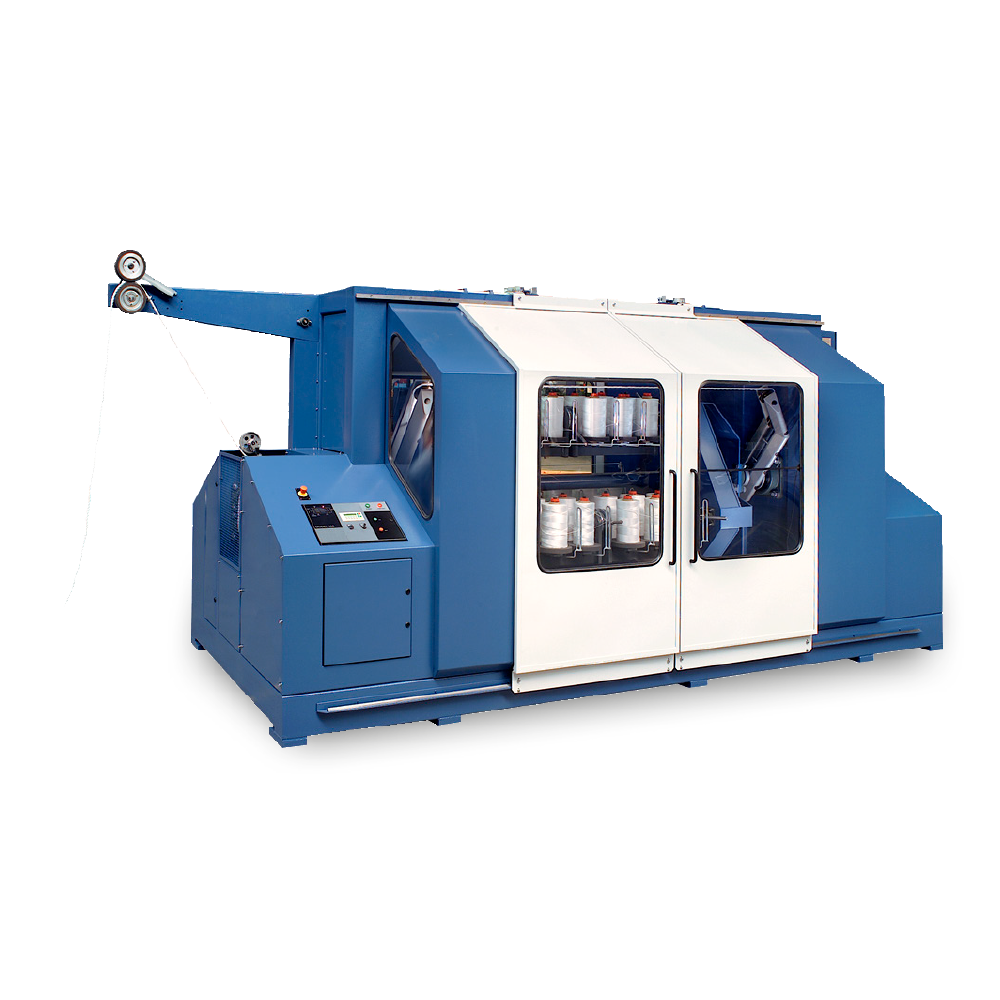

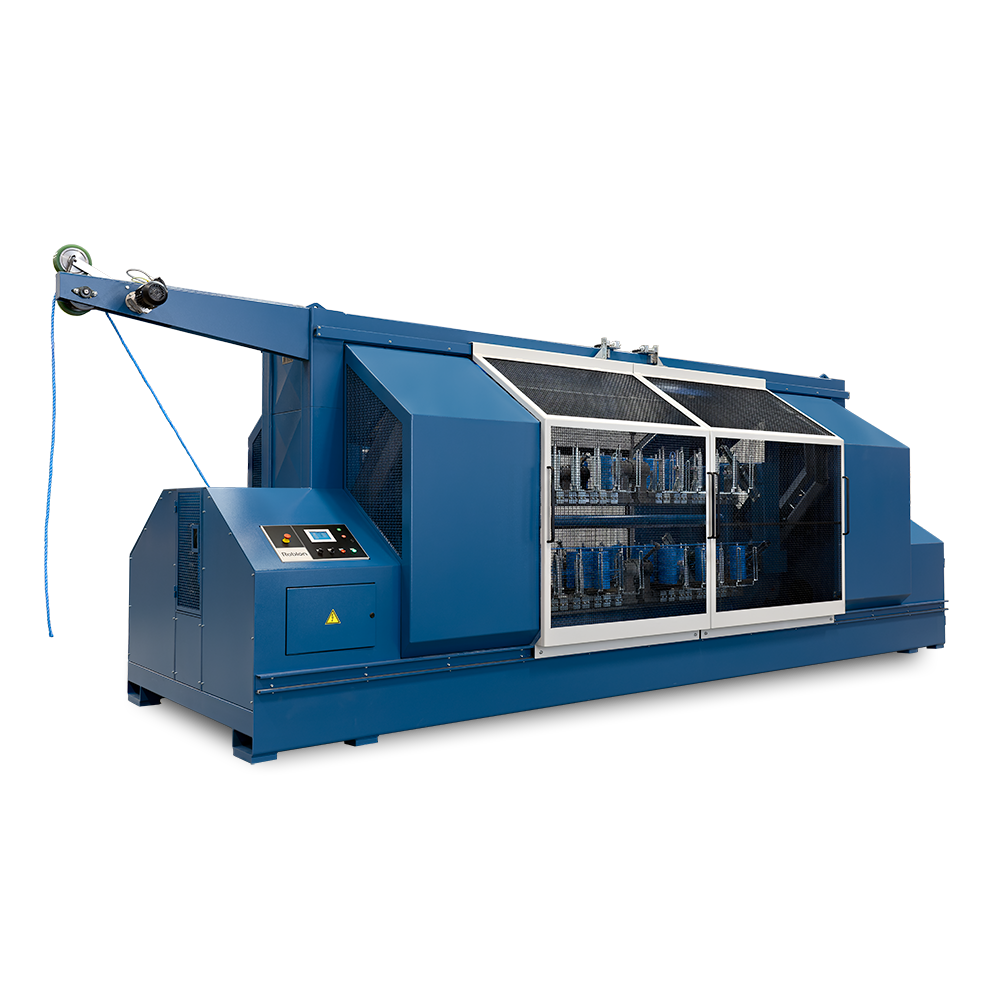

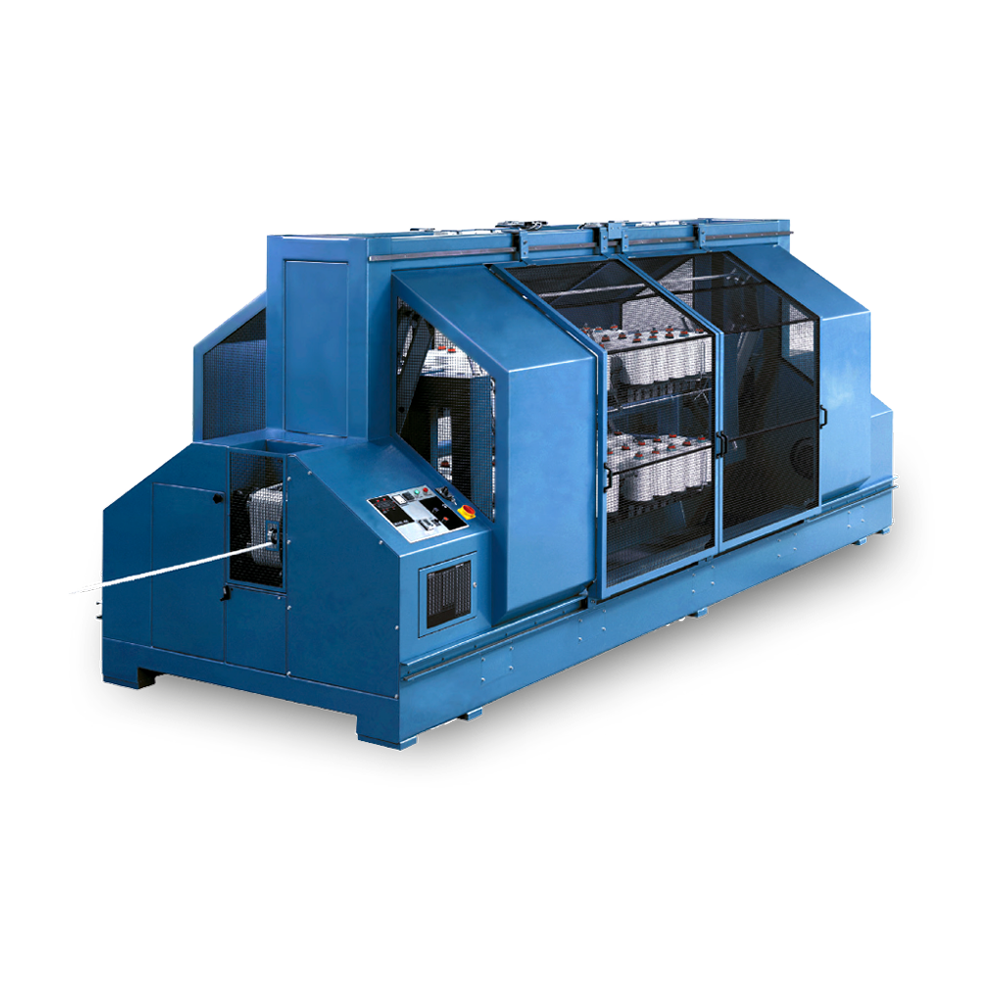

Rope making the Robco way

Producing rope on conventional rope making machines usually involves the following three operations:

- Stranding

A stranding machine twists the yarns to form individual strands, typically winding them onto large flange reels. - Closing (laying)

In this phase, operators layer strand bobbins and tie their ends together using waste strands from prior production. They then twist these strands together and wind them onto an even larger flange reel. - Coiling

Finally, the rope is re-wound to obtain coils of required length and/or dimensions.

However, on a Robco rope making machine, this three-stage process is carried out in one continuous operation on a single rope machine. This is possible as the system is based on the two-for-one principle – i.e., two rope lays per revolution compared to one rope lay on a conventional rope making machine.

Apart from the obvious advantage of capacity, the two-for-one principle makes it possible to avoid rotation of all heavy parts. This again means low energy consumption and low noise level. Also, much of the hard manual work is avoided. Finally, this production method reduces the waste immensely.

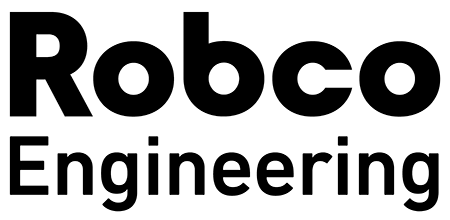

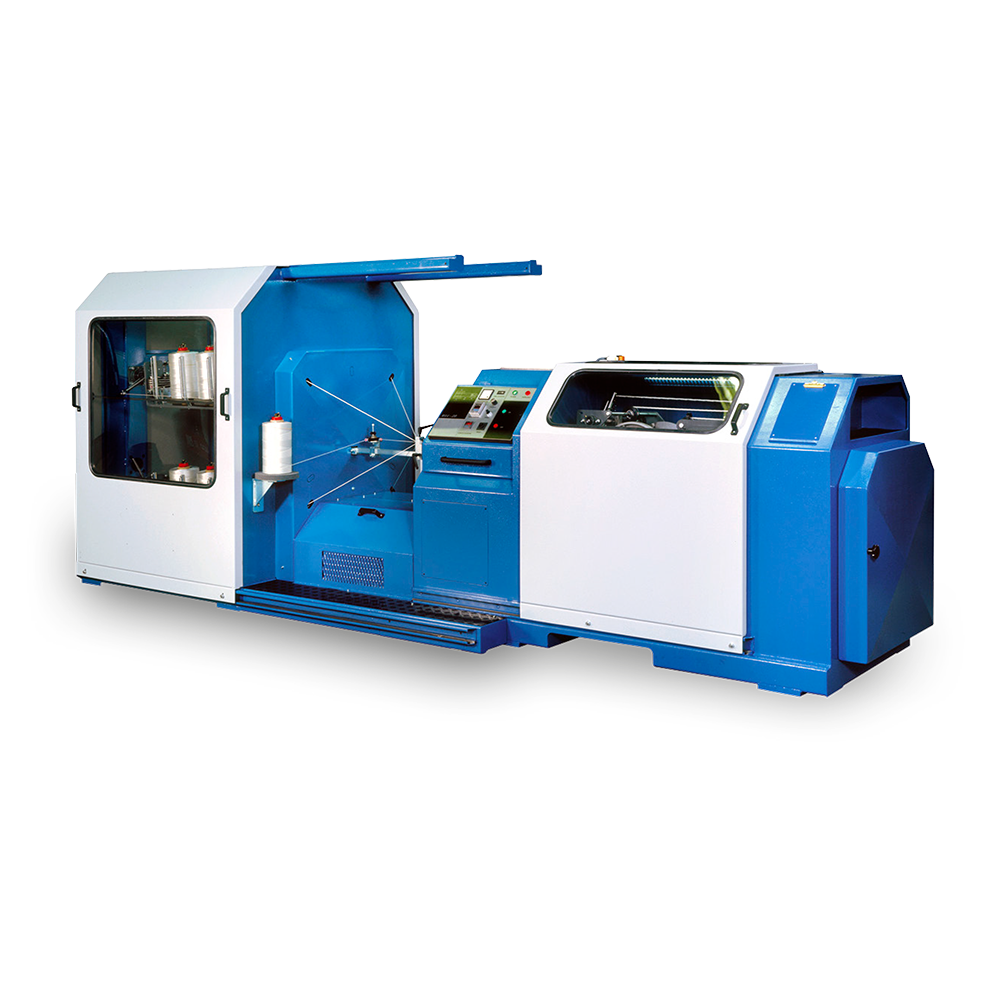

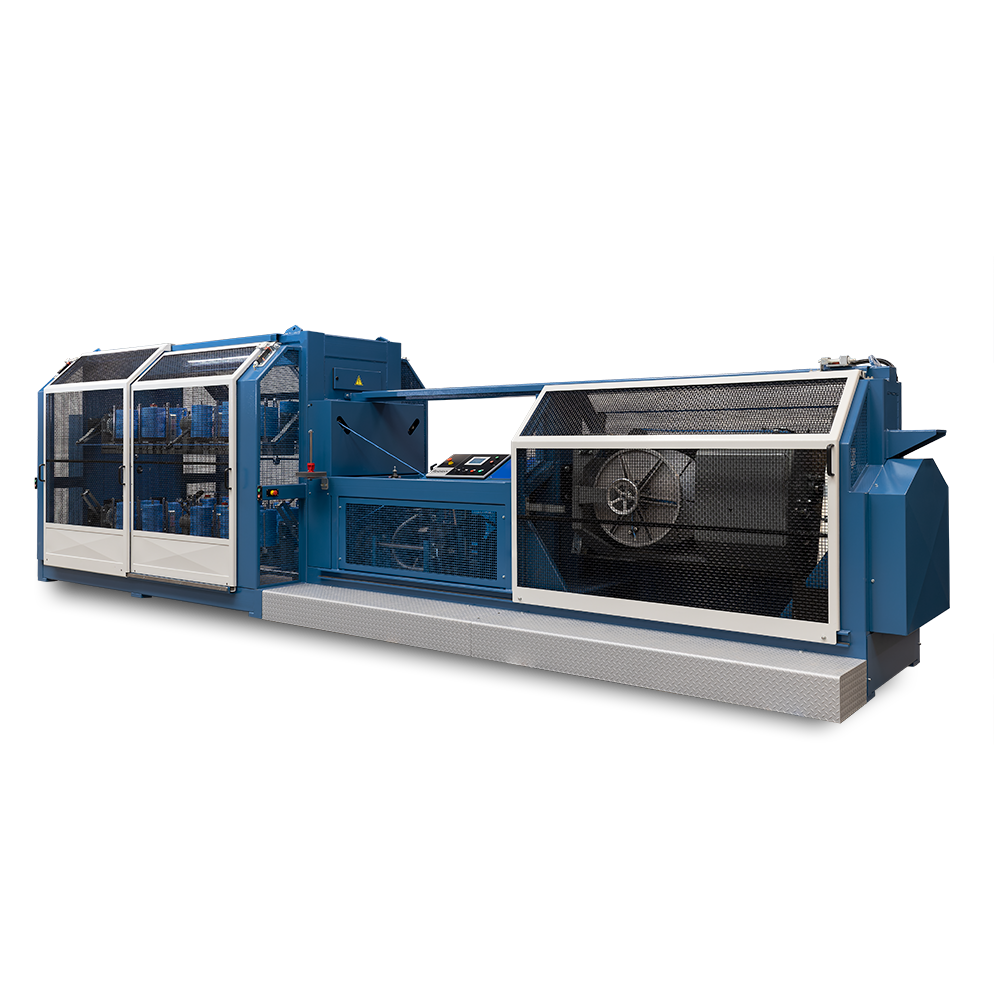

The Robco rope making machines cover a rope range from 2 mm to 52 mm diameter.

See the M177 rope making machine in action below

To illustrate how the rope making system works, we have outlined the main principles below:

- The rope making machine consists of two parts: the stranding section in which each strand is twisted, and the closing section in which the strands are twisted together.

- The stranding section consists of three (or four) creels on which the pay-off bobbins are placed. These may either be flange spools or cross wound bobbins (on tubes or tubeless). The pay-off bobbins may also come directly from the extruder winders.

- The yarn from each pay-off bobbin is led through to the flyer arms, which are positioned on either end of each creel. Once the flyers are set in motion they provide the yarns with the first two twists – thereby producing the actual strand. On their way from the stranding section and into the closing section, the strands pass through the rope die, which helps form the finished rope.

- The closing section consists of a cradle in which the capstans and the coiling arrangement are placed.

- The rope flyers, which are placed on each side of the cradle, provide the finished rope with the last two twists.

The ROBCO range covers both rope making machines as well as twisting machines, rope winding machines, stranding machines and winding machines.