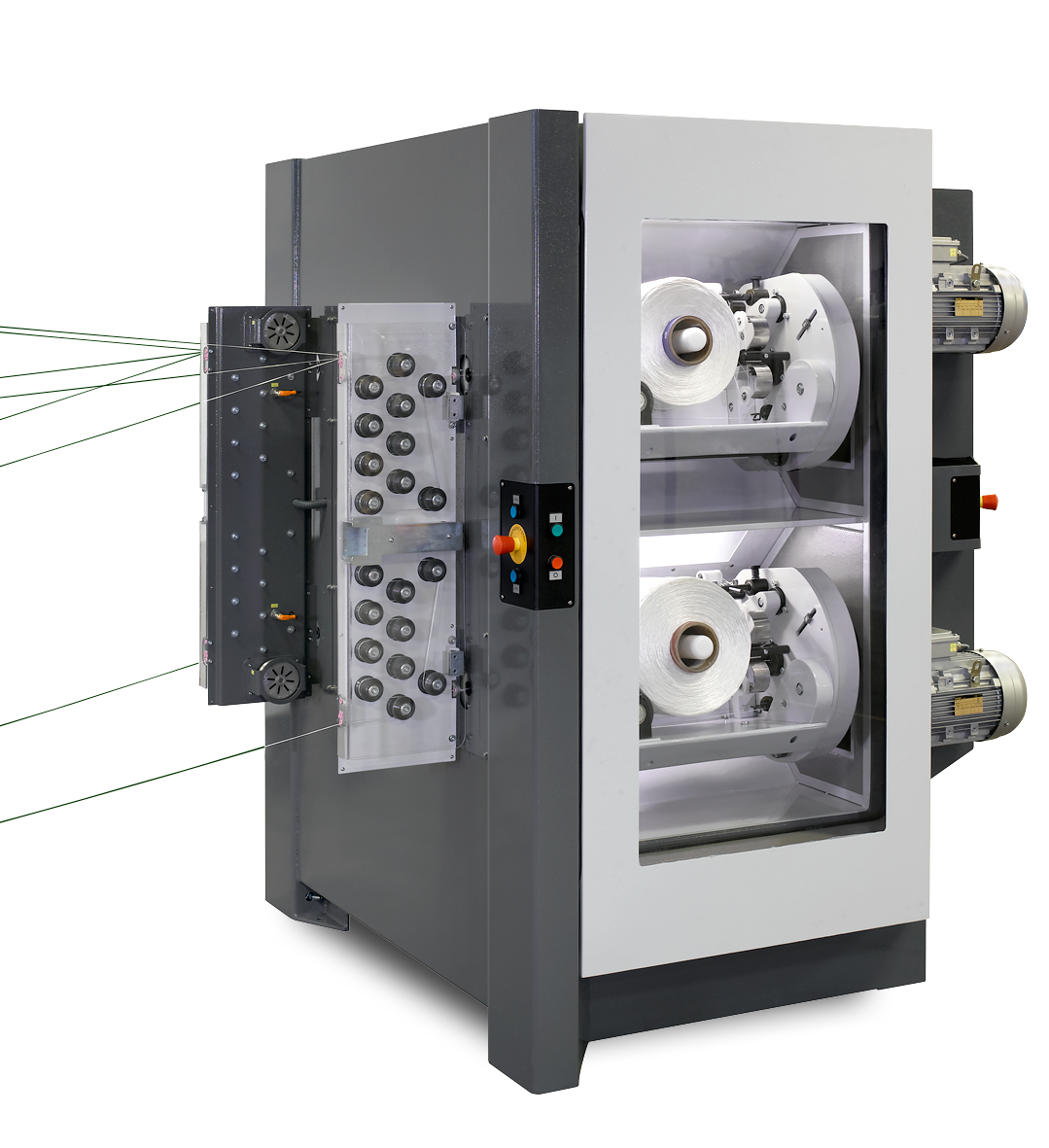

Twisting machines play a crucial role in various industries where the production of strong, reliable yarns and twines is essential. The Robco twisting machines follow the same innovative principle as our renowned rope making machines, ensuring efficiency and high performance.

Our twisting machines are utilized across a spectrum of industries, from textile manufacturing to agricultural applications. They are all highly suitable to produce rope yarns, industrial fibers, paper cord, tying twine and baler twine. Moreover, these machines can ply pre-twisted yarns, offering flexibility in manufacturing processes.

Our Tornado twister can be used for heavy twine up to 220,000 denier and for light yarns down to 5,000 denier. Our T55, T66 and T77 are very suitable for production of cable filler yarns from 65,000 to 1,350,000 denier.

The Robco twister machines are of a rugged and simplified design with many high-quality features. Among other things, the transmission to the take-up package is a hydraulic, closed system which is almost maintenance-free. Most of the inner transmissions consist of timing belts which are very sturdy and noiseless.

Upon completion of the twisting process, the finished twine is wound onto either cardboard tubes or directly onto a tapered spindle. This flexibility allows to produce tubeless packages, catering to different requirements based on the specific model and type of twisting machine.

Watch the Tornado 300 twisting machine in action below

The ROBCO range covers both twisting machines as well as rope making machines, rope winding machines, stranding machines, and winding machines.